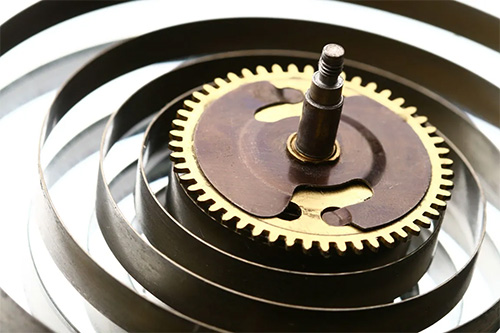

涡卷弹簧

Spiral Torsion Springs also known as clock springs, flat spiral spring or spiral torsion springs, they are typically manufactured from high carbon steel or stainless steel that wound in the flat state, and are characterized by the condition that their coils do not contact during operation, the inner end of these springs are fixed and the other end attached to the other components that is rotating the spring torque. This design offers reduced force, also reduce friction to zero (coil friction free) when installed correctly.

Spiral Torsion Springs are the most commonly used type of flat spring and are sometimes used in place of the traditional torsion spring as they rotate in circular movements, the torque deliver per revolution is linear for the first 360 degree, at greater angular rotation, the coils begin to close on the arbor and the torque per turn increases rapidly also per revolution on nonlinear when closer to the axis, thus these type of springs are ideally suited for applications requiring less than 360° of angular rotation.

Our custom designed Spiral Torsion Springs are available in a variety styles, sizes and materials, this makes power springs useful in a wide variety of applications, with this complete selection of styles available, our experienced engineers can help you select a spring design to meet your needs.

Various materials, including carbon steel, stainless steel, and specialty alloys, are available for spiral torsion spring development projects or prototypes. Each metal provides the following distinct advantages:

1. Carbon Steel: Widely used for engineering springs, carbon steel may require pre-galvanized coatings or additional corrosion protection.

2. Stainless Steel: Stainless steel exhibits excellent heat and corrosion resistance properties and is an essential metal alloy for manufacturing spiral torsion springs.

3. Specialty Alloys: Metals such as chromium alloys and cold-drawn nickel are best suited for applications requiring high corrosion resistance when exposed to extreme temperatures.

Spiral Torsion Spring Mounting Methods

Mounting methods vary based on the type of spring and can include the following:

1. Back-to-Back Mounting: Considered the most stable mounting method, back-to-back mounting features two springs attached back-to-back, allowing them to unwind in opposite directions. The configuration prevents twisting and is ideal for applications with long extensions.

2. Tandem: One spring is placed behind another, leaving a small space between the two devices. This mounting method is not as stable as other methods, so its best suited for applications with limited space for back-to-back mounting.

3. Laminar: The laminar mounting method interwinds multiple springs, creating an optimal solution for working in confined spaces. Laminar mounting takes up less space than a singular spring and can offer more force from the shorter extension.

4. Cavity: A low-cost alternative, cavity mounting is easy to assemble, as it does not require bushings, but friction can be a limiting factor. The spring gets mounted in a cavity, where it encounters constant contact and friction during movement. A cavity-mounted design must incorporate additional considerations to address this issue.

Flat spiral torsion springs offer a wide range of advantages. These mechanical devices are extremely durable and long-lasting, providing good value for their cost. Spiral torsion springs are also easy to use and adjustable for use in vehicles and other applications. They are relatively small, allowing them to fit in various settings, especially those with limited space.

For further information about Spiral Torsion Spring Customization, please contact our sales.